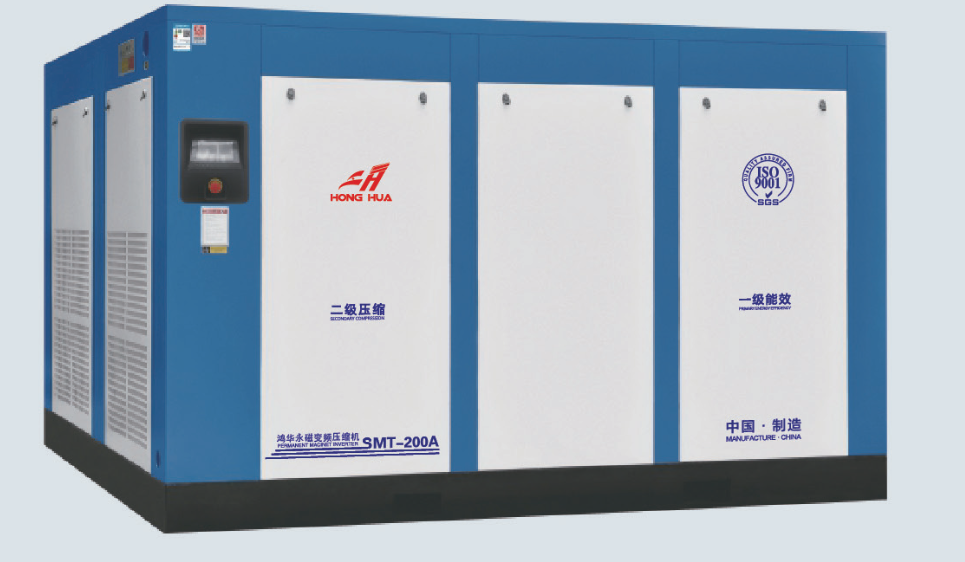

Honghua SMT series two-stage compression permanent magnet variable frequency air compressor (super energy-saving model)(SMT20HP-500HP))

Cooperation between two-stage compression and permanent magnet variable frequency motor

. The permanent magnet moor adopts high-perfarmance neodymium iron boron permanent

magnets, no loss of magnetsm at 120℃, and a senvice ife of over 15 years.

.The stator coil adopts coronar-resistant enaneled vire specaly designed for frequency

corverter. Excelent insulation performance and longer service life.

. it can realze a soft start When nunning, the motor curent wil not exceed the full load cument

and at the same tme, the impact on the gid equipment wil be greatly recuced, and the

lelectrical equlipment will not be damaged.

. No motor bearing: the rotor with permanent magnets is directly mounted on the extended

shaft of the male rolor. This structure does not require the use of bearings, thereby eiminating

the point of falure of the motor bearing

Energy saving analysis of screw two-stage compression

After the air is compressed in the first stage, it is cooled by enhanced oil injection to reduce the temperature of the second stage suction, and the air is compressed in the second stage to reduce the compression work ratio.

Two-stage compression uses equal pressure ratio to set the inter-stage pressure, so the compression ratio of each stage is much lower than the single-stage compression ratio, the retum nleakage between the rotors is greatly reduced, and the volumetric efficiency and adiabatic efficiency are greatly improved. Correspondingly, the compressed gas production is increased. Under the same power, the gas output of two-stage compression is 35% higher than that of single-stage compression, which can achieve up to 35% energy saving effect.