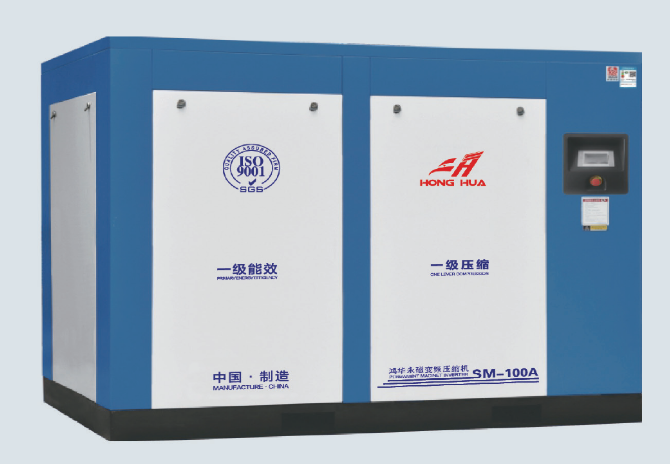

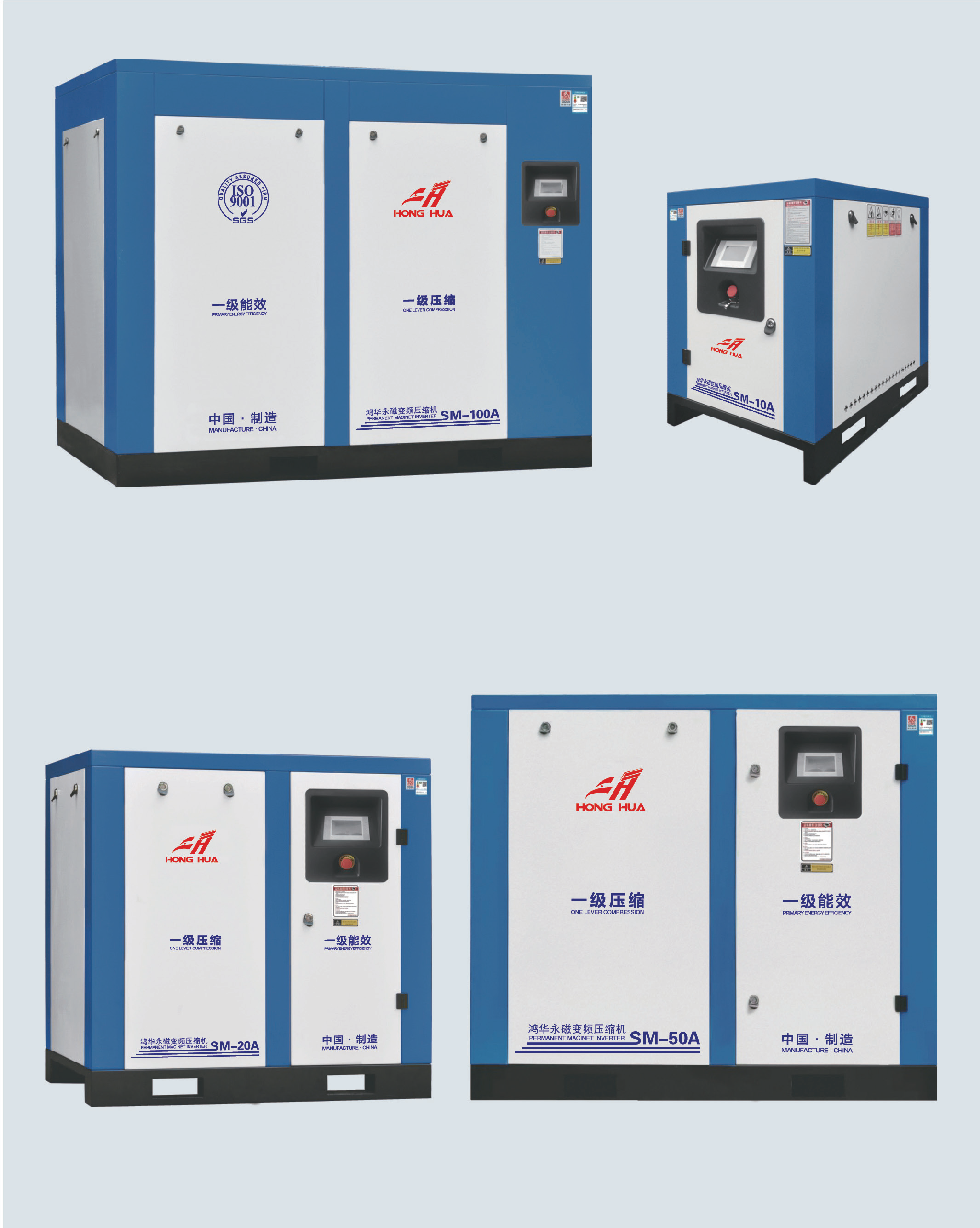

Honghua SM series one-stage compression permanent magnet variable frequency air compressor (energy-saving model)(SM10HP-380HP)

Characteristics of permanent magnet integrated machine

One shaft type structure

1.Permanent magnet motor and airend use the embedded integrated shaft connecting structure, more compact, 100% transmission efficiency.

2.No motor bearings, eliminating the motor bearing fault points.

Different speeds, permanent magnet motor with high efficiency, remarkable energy-saving effect

1.At rated speed point, permanent magnet motor efficiency is higher than ordinary motors.

2.Under low motor speed, permanent magnet motor can still keep high motor efficiency. If the gas consumption less, it still keeps extremely high efficiency. Compared with common frequency conversion motor, the motor efficiency appears obvious gap and the air compressor has effective energy saving.

Small volume, low noise

It has the integrated structure, configuration of high efficiency permanent magnet motor, small size, saving space, easy disassembly. Deloying efficient permanent magnet variable frequency controllor, it can change the speed of the permanent magnet motor according to the exhaust volume, it will achieve lower operation noise than ordinary ones.

Stable operation

1.Permanent magnet motor has high performance NdFeB permanent magnet, 120℃ without loss of excitation, and service life of over 15 years.

2.Stator coil adopts special inverter corona resistant enamelled wire. Insulation performance and longer service life.

3.Realizing soft start, the motor current will not exceed the full load current during operation, and greatly reduce the impact on network equioment. no damade to electrical equipment.

Energy saving advantages of permanent magnet air compressor:

Condition energy saving

The permanent magnet motor remains high efficiency at low speeds, ensuringobvious energy-saving advantages in small air volume.

·Frequency range from 0%-100% (common conversion from 60%-100%)

·Compared with the fixed speed compressor, energy saving 22%-40%

●Compared with the common inverter compressor, energy saving 5%-15% System volume fluctuations larger, then energy-saving effect more obviously.

Energy saving system of unloading (inverter)

According to the stationary air compressors in gas consumption fluctuation, it has the unloading time, then the air compressor idling but also need 45% of the electricity, but the permanent-magnet frequency air compressor will control for inverter, no unloading and no waste. If the air compressor units become larger, energy saves more.

Save the wasted electric energy by pressure control bandwidth (energy saving)

Fixed compressor must set a minimum control pressure for the 1Barg band (i.e.air compressor limits) to avoid the impact on the unit and the power grid. Several machines must use together with a pressure gradient, more wide pressure, while the HongHua permanent-magnet variable-frequency Air compressor series is inverter control, unlimited stop, no need to set pressure, but a pressure point on the line. The pressure of each 0.14Barg bandwidth, the system can save energy 1%.

Energy saving startup (inverter)

Air compressor’s starting current is 3-6 times of the rated current, the frequently start will waste a lot of energy, and frequency conversion type has no frequent starting and stopping, but soft start. The maximum current does not exceed the rated working current, no energy waste. At the same time also greatly reduce the impact on network equipment, and no damage to electrical equipment.